Prof. Driscoll and her group’s research interests are in the area of ‘Energy Efficient Oxide Materials for ICT and Oxide Energy Devices’. To both create and understand new oxide energy devices, we undertake nanoscale design and tuning of thin film materials. Our aim is to improve the performance of the films as well as overcome their complexities in terms of compositions, defects and interfaces. We also create test device structures down to 10’s nanometre length-scales.

We have world-leading growth equipment, principally:

-

Pulsed laser deposition with RHEED control of growth and in-situ XPS.

-

High-temperature oxide sputtering with controlled angle deposition.

-

Atmospheric pressure spatial ALD. We launched a start-up on the machine in 2023.

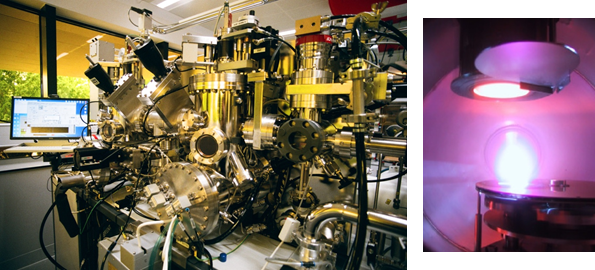

Fig. 1. Group's growth equipment.

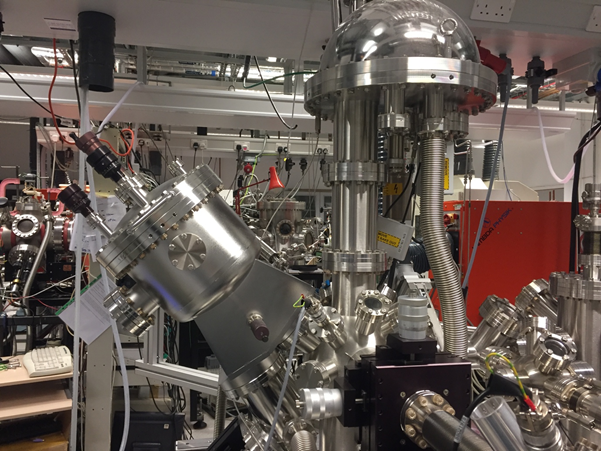

Fig. 2. Advanced pulsed laser deposition systems (one system with in-situ XPS) used in Prof. Driscoll’s group.

We use a very wide range of characterisation tools (materials characterisation and electrical characterisation) within our group and outside the group to learn about the properties of the materials and devices. We collaborate widely across the University and the world both with academics and industry. We are very fortunate to have such a great team of excellent and like-minded people with complementary expertise.

Collectively, we bring together the wide-ranging skills that are essential to solve some of the most complex materials challenges of our time, particularly in respect to trying to mitigate climate change. The role of Driscoll (and group) is often to think of the right materials for the desired functional goals, predict and demonstrated how they can be fabricated optimally in nanostructured thin film device form, and then do basic understanding of how and why they behave as they do.